In the world of GNSS surveying, accuracy and efficiency are the keys to success. Traditionally, surveyors have had to ensure that their survey poles were perfectly vertical to achieve precise location measurements. However, with advancements in technology, RTK (Real-Time Kinematic) receivers now incorporate IMU (Inertial Measurement Unit)tilt sensors, allowing users to capture data faster and with greater flexibility.

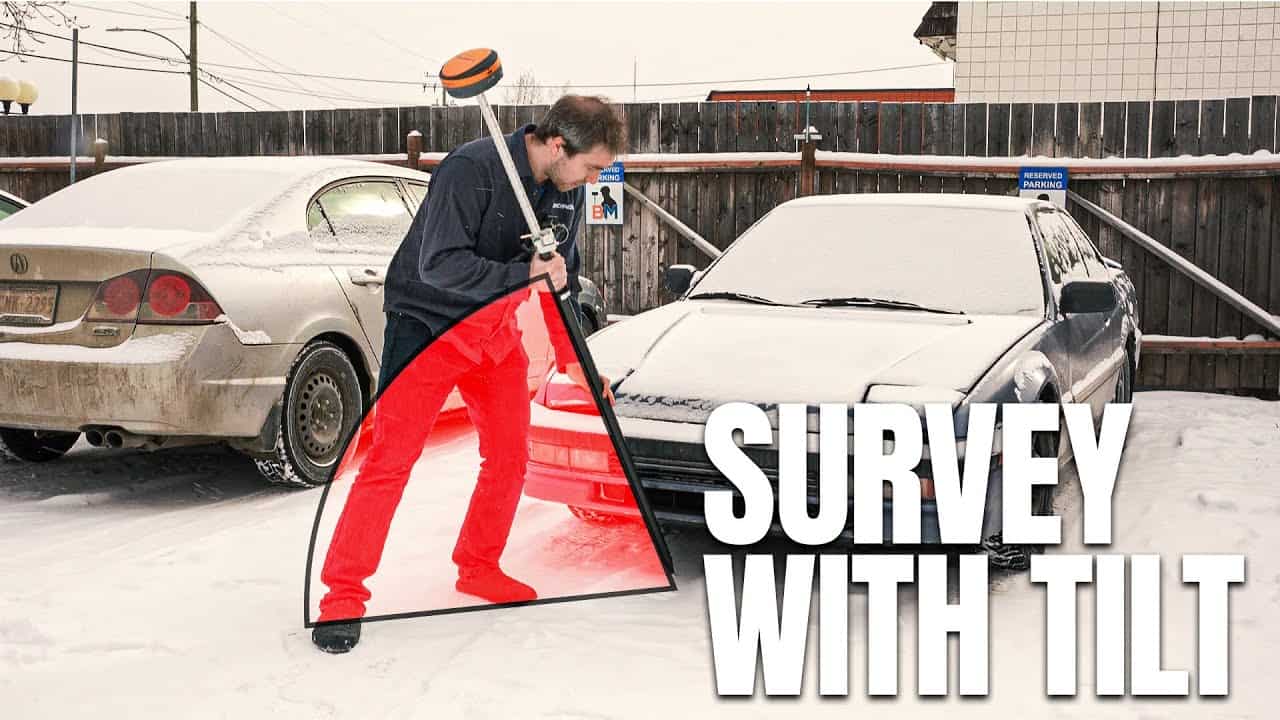

This article explores how an IMU tilt sensor functions in an RTK receiver, the benefits and drawbacks of this technology, and how it can be effectively utilized in the field. You can also check out our below video on tilt sensors!

What is a Tilt Sensor in an RTK Receiver?

Evolution of Tilt Sensors in RTK Receivers

Benefits of Using an IMU Tilt Sensor in an RTK Receiver

How to Calibrate and Use the IMU Tilt Sensor

A tilt sensor in an RTK unit is designed to compensate for the inclination of the survey pole, adjusting the reported position to account for the angle of the pole tilt. The tilt sensor corrects the angle of the tilt so the reported position of your receiver is as if the survey pole was plumb. With a tilt sensor surveyors no longer need to hold the pole perfectly upright to capture accurate data. With the tilt sensor enabled, you can record points significantly faster than if you didn’t have it enabled.

Tilt sensors are not a brand-new innovation in GPS receivers. Previous generations of RTK receivers had tilt sensors that relied on magnetic compasses. These early models required extensive calibration before use, which made them cumbersome and inefficient for practical field applications.

The calibration process for these older models, like the Hemisphere S321, involved placing the receiver on specialized brackets, rotating it through a tedious process, and having to perform the calibration for every battery. This had to be repeated frequently, especially when moving to a different geographic location where the magnetic declination was different relative to the original calibration method. If not done properly, the calibration can produce significant errors.

Modern IMU-based tilt sensors, however, have revolutionized this process. Unlike magnetic tilt sensors, an IMU-based tilt sensor does not require constant recalibration due to environmental changes. This makes them far more practical and efficient for real-world surveying applications. Down below we will show you how to calibrate your IMU tilt sensor.

An IMU tilt sensor consists of accelerometers and gyroscopes that measure movement and orientation. This is the same technology used in submarines, aerospace systems, and other navigation applications where GPS signals may be intermittent or unavailable.

Here’s how it functions in an RTK receiver:

1. Motion Detection – The accelerometers detect linear acceleration, while the gyroscopes measure angular velocity. These combined inputs allow the IMU to determine the orientation of the receiver.

2. Continuous Position Adjustment – As the pole tilts, the IMU uses these measurements to calculate the precise ground position based on the known HI.

3. Integration with RTK Corrections – The RTK system provides centimeter-level accuracy by processing real-time satellite corrections, and the IMU tilt sensor ensures that even if the pole is not vertical, the true location is still recorded accurately.

4. No Magnetic Interference – Unlike older tilt sensors, IMU-based units do not rely on magnetic readings, eliminating issues related to nearby metal objects or magnetic declination variations.

The introduction of IMU-based tilt sensors in RTK receivers has significantly improved surveying workflows. Most 7thgeneration RTK receivers contain an IMU sensor, so you need to understand the trade-offs of this technology. Some of the key advantages include:

1. Faster Data Collection

Surveyors can now capture data almost twice as fast because they no longer need to level the pole before each measurement. This is especially beneficial in large-scale topographic surveys where efficiency is crucial.

2. Ability to Measure Hard-to-Reach Points

In many surveying scenarios, obstacles such as buildings, vehicles, or terrain features make it difficult to place the receiver directly over a point. With an IMU tilt sensor, users can tilt the pole and still collect accurate data without having to physically access the point.

3. Improved Safety in the Field

Surveyors often work in challenging environments, such as construction sites, busy roads, or uneven terrain. The ability to collect points without maintaining perfect pole positioning reduces the need for risky maneuvers, enhancing safety. For instance, while surveying the centerline of a road, rather than keeping your eye on the bubble you can keep your eye on traffic.

4. Enhanced Topographic Surveys

When mounted on a moving vehicle, such as an ATV, an IMU tilt sensor compensates for the changing orientation of the receiver, ensuring accurate elevation readings even when traversing slopes and curves. This can make driven topographic surveys a lot more practical. Check out how we used the tilt sensor to a topographic survey to build swales on a farm:

While IMU-based tilt sensors offer numerous benefits, they are not without their limitations. Here are some important considerations:

1. Slight Accuracy Trade-Off

Using a tilt sensor introduces a small margin of error. Typically, it adds about 2 cm of uncertainty at the bottom of the pole. Although this is minor in most applications, surveyors working on high-precision projects should take this into account. You can see how this comes into effect in our testing on the IMU tilt sensor with the Hemisphere S631.

2. Importance of Accurate HI Measurement

Since the tilt correction is based on the entered HI, any errors in measuring the height of the instrument will propagate into the final dataset. Surveyors must ensure that the HI is correctly inputted to maintain accuracy.

To make full use of the IMU tilt sensor on an RTK receiver like the Hemisphere GNSS S631, follow these steps:

1. Set the HI Correctly – Ensure the receiver’s HI is measured accurately and entered into the software.

2. Enable Tilt Correction – Activate the tilt correction feature in the receiver’s settings.

3. Initialize the IMU – Rock the receiver back and forth a few times until the system indicates that initialization is complete.

4. Start Collecting Data – With the tilt sensor activated, you can now capture points without needing to level the pole.

5. Verify Accuracy – If working on a critical project, verify the tilt-corrected measurements by comparing them with traditional methods.

IMU-based tilt sensors in RTK receivers have transformed workflows in various industries, including:

– Construction: Quick and accurate layout of site features without the need for leveling. If you are doing a lot of pickup or grade checks the tilt sensor will make you a lot faster.

– Land Surveying: Faster collection of boundary and topographic points. With the tilt sensor you can shoot points through fences, under cars and get out from under eaves when next to buildings. Instead of having to break out the total station or perform an asset, you can just record your points.

– Utilities and Infrastructure – Improved efficiency in mapping underground and above-ground assets.

– Forestry and Environmental Studies – Easier data collection in dense vegetation and rugged terrain.

The integration of IMU tilt sensors in RTK receivers represents a major leap forward in GNSS technology. By eliminating the need for precise pole leveling, surveyors can work faster, access difficult locations, and improve overall efficiency. While there are slight trade-offs in accuracy, proper setup and usage ensure reliable results for most applications.

As GNSS technology continues to evolve, IMU tilt sensors will likely become standard features in high-precision RTK receivers, making surveying faster and more accessible than ever before.

The primary advantage of an IMU tilt sensor is that it allows surveyors to collect data much faster by eliminating the need to level the pole for each measurement. This speeds up workflows significantly, especially in topographic surveys and construction layout tasks.

An IMU tilt sensor enables surveyors to record accurate points even when the pole is tilted. This is particularly useful when measuring points under obstacles like vehicles, buildings, or dense vegetation, where a traditional vertical pole setup would be difficult or impossible.

No, IMU-based tilt sensors do not require frequent recalibration like older magnetic tilt sensors. They use accelerometers and gyroscopes to measure motion and orientation, eliminating the need for magnetic readings and reducing the impact of environmental factors such as magnetic declination.

IMU tilt sensors typically introduce a small margin of error, adding about 2 cm of uncertainty at the bottom of the pole. While this is minor in most applications, high-precision projects may require additional verification or adjustments to compensate for this variation.

To initialize the IMU tilt sensor, enter the correct HI (Height of Instrument) into the receiver, enable tilt correction, and rock the receiver back and forth to complete the IMU initialization. Once set up, you can capture points without leveling the pole, ensuring greater efficiency in the field.

Bench Mark Equipment & Supplies is your team to trust with all your surveying equipment. We have been providing high-quality surveying equipment to land surveyors, engineers, construction, airborne and resource professionals since 2002. This helps establish ourselves as the go-to team in Calgary, Canada, and the USA. Plus, we provide a wide selection of equipment, including global navigation satellite systems, RTK GPS equipment, GNSS receivers, and more. We strive to provide the highest level of customer care and service for everyone. To speak to one of our team today, call us at +1 (888) 286-3204 or email us at [email protected]