Modern surveying is evolving quickly, and 3D laser scanning is driving that transformation. In the past, capturing site conditions required tapes, total stations, and a great deal of manual measurement that often didn’t align perfectly later. Today, land surveyors, engineers, and construction teams can record millions of precise measurements in just minutes.

At Bench-Mark, we work with survey crews across North America who are transitioning from traditional workflows to digitally capturing full 3D models. One of the most common questions we hear is simple: what can 3D laser scanning actually do for a survey team, and how does it become something usable back in the office?

This guide explains how 3D scanning works, when it makes sense to use it, and how it produces the digital twins that engineers, architects, and owners rely on.

What Is 3D Laser Scanning in Surveying?

How a 3D Laser Scanning Survey Works

Where 3D Laser Scanning Excels

From Scan to Digital Twin

Why Surveyors Are Adopting 3D Scanning

Common Challenges and How Crews Overcome Them

3D Scanning vs. Traditional Surveying

Final Thoughts: From Field Reality to Digital Twin

FAQs

3D laser scanning, also known as LiDAR, high-definition scanning, or reality capture, is a method of measuring real-world objects using a laser sensor. The scanner sends out laser pulses, measures the return time, and calculates the precise 3D location of each reflected point.

A traditional total station captures a limited number of points. A 3D laser scanner collects millions of points per second. These points form a point cloud which is a dense, accurate representation of a site, structure, or infrastructure component. A clean point cloud provides the foundation for a wide range of deliverables, including:

With the right workflow, a 3D scan becomes a digital snapshot of reality that can be revisited anytime.

Set up the scanner, press start, and wait. The true value lies in the full workflow that connects field capture to the final deliverable.

The scanner is placed on a tripod or vehicle and fires laser pulses in every direction. Each pulse becomes a data point in 3D space. Modern scanners record over a million points per second across hundreds of meters, capturing a complete 360° view. Multiple setups are typically required to eliminate shadows and ensure full coverage. Control points or GNSS references are used to tie everything into the project coordinate system.

Back in the office, or sometimes directly in the field, each scan is aligned to form a single, unified dataset. Proper registration delivers millimeter-level accuracy and preserves the true geometry of all vertical and horizontal surfaces.

Specialized software then removes unwanted noise such as vegetation, people, or vehicles, leaving a clean and workable dataset.

Modeling and Deliverables

The refined point cloud becomes the foundation for 2D CAD drawings, 3D surfaces, BIM models, or even full digital twins. This stage is where scanning proves its worth, transforming raw data into actionable design intelligence.

3D laser scanning has applications across nearly every discipline of surveying and engineering.

Subdivision layouts, grading, utilities, and retaining walls can all be captured in one pass, replacing hundreds of rover shots and eliminating missed areas. Surveyors gain faster earthworks volume calculations and more accurate terrain models.

Measuring bridges, roads, tunnels, or rail corridors has traditionally been time-consuming and risky. Laser scanning allows crews to work safely from the shoulder or sidewalk, without shutting down traffic or entering confined spaces.

When floors aren’t level, walls are out of plumb, or MEP systems deviate from design, scanning provides the truth. Contractors use this data to check steel alignment, verify installations, and assess slab flatness or façade tolerances.

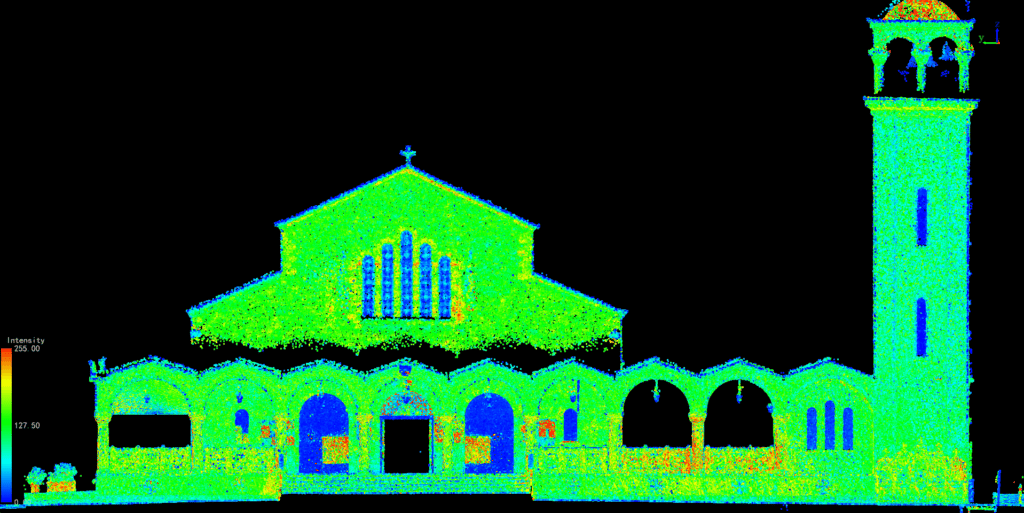

For restoration or preservation projects, scanning records every detail of existing structures, ensuring millimeter-level documentation and accuracy that drawings alone can’t capture.

In complex facilities filled with equipment, conveyors, and piping, scanning enables measurement without halting production.

A digital twin is a living, data-rich 3D model of a real-world asset. With a digital twin, project teams can plan renovations, detect design clashes, run simulations, and take precise measurements without revisiting the site.

The digital twin becomes a long-term resource for asset management, helping owners maintain accurate records for decades. Engineers trust it. Contractors save money with it. And project owners appreciate the confidence it brings to decision-making.

Survey teams are moving to laser scanning for clear reasons:

Like any advanced tool, 3D scanning introduces some difficulties that you may face initially. The main challenges include hardware cost, software complexity, and large data files that demand powerful computers. Poor scan planning can also compromise accuracy.

At Bench-Mark, we’ve guided many survey teams through the transition without overextending budgets or schedules. The most successful ones start small with scanning a pump room or a bridge deck before tackling full sites. They also tie every scan to proper survey control using GNSS and rely on compatible software that converts point clouds into CAD, surfaces, or BIM models.

Both methods have their place. Traditional GNSS and total station workflows are best for boundary surveys and simple topography. At the same time, 3D scanning works well in complex structures, industrial environments, or detailed as-built verification. Most surveyors use both, choosing the method that best fits each project’s scope and precision requirements.

3D laser scanning has become a standard part of modern surveying. It enables better accuracy, fewer site visits, safer data collection, and reliable as-builts that support long-term asset management.

When you’re just beginning your journey or refining your scanning workflow, Bench-Mark is here to help. We support surveyors across North America with equipment, training, and hands-on technical expertise built on real solutions for real crews.

Traditional methods capture individual points manually. A 3D scanner captures entire surfaces, which gives far more detail and accuracy.

Yes. With GNSS or control points, point clouds can be georeferenced just like total station data.

You do. Programs like AutoCAD, Revit, and Trimble RealWorks convert point clouds into usable drawings and models.

Not at all. Many surveyors use scanners for small structures, elevations, or interior verification.